Product search

BPC10, BPC11, BPC90, BPC91

The fourth industrial revolution opened dialogue between IT and industrial control.

China is actively implementing Made in China 2025, and Germany is promoting Industry 4.0, and these are providing comprehensive integration schemes for the use of sensors and big data in industrial computers.

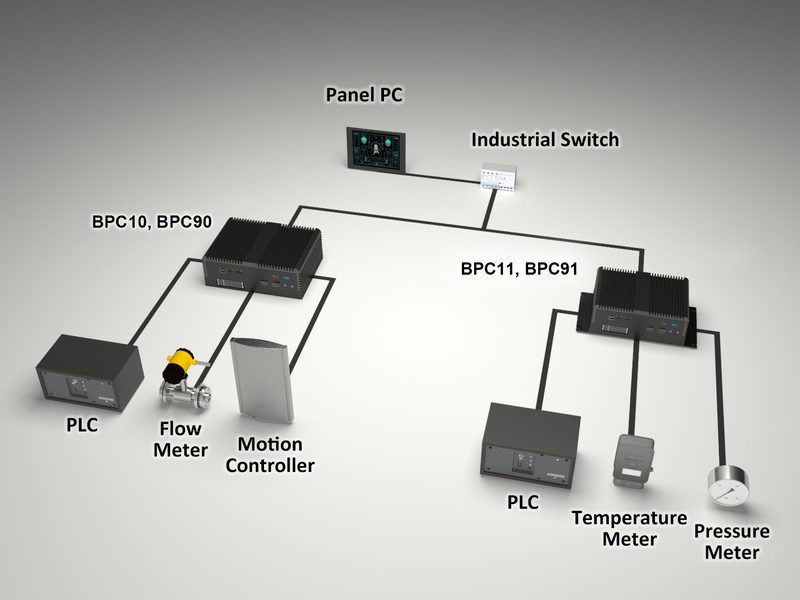

Every aspect of the equipment belonging to the smart factory of the future will have a capacity for independence, and when applied to fully automated production line operations, the pieces of equipment will be able to communicate between themselves, effect real-time monitoring, and resolve problems, making the production process more flexible and adaptable to a greater diversity of client demands. EBN provides a gateway that can reliably connect in series all aspects of important equipment, effectively achieving the objective of intelligent production.

繁體中文

繁體中文

English

English

日本語

日本語